For brands entering the footwear market, materials can make or break a product. It’s not just about design, it’s about substance: how the shoe feels, performs, and communicates the brand’s intent. And while big names have long benefited from dedicated material labs and exclusive supplier networks, that same level of access is becoming increasingly available to smaller, more agile brands using the right sourcing companies.

Vietnam, now a global leader in footwear production, has quietly built a powerful material development ecosystem one that’s uniquely suited to support the needs of scaling brands. From upper textiles to outsole compounds, sourcing companies like Locol Design and Source with local development teams are helping bridge the gap between creative vision and commercially viable product.

Here’s how they do it:

-

Upper Materials Aligned to Aesthetic and Performance Goals

The upper is often where brand identity lives, from layered mesh and engineered knits to suedes, synthetics, and ripstop textiles. But for challenger brands, sourcing the right materials can be overwhelming: options are vast, MOQs are high, and performance isn’t guaranteed.

Companies with material development teams on the ground provide vital support by sourcing and fine-tuning upper materials that align with both design intent and practical requirements. Need a breathable textile with a premium hand feel? A recycled synthetic that hits a target cost? A dyeing process that matches brand colours while meeting sustainability targets? These teams work closely with regional suppliers to identify or develop materials that hit the brief, aesthetically, functionally, and financially.

Proximity to sampling facilities and production lines also means brands can test new materials quickly and adapt based on fit, finish, or durability feedback, saving critical time during development.

-

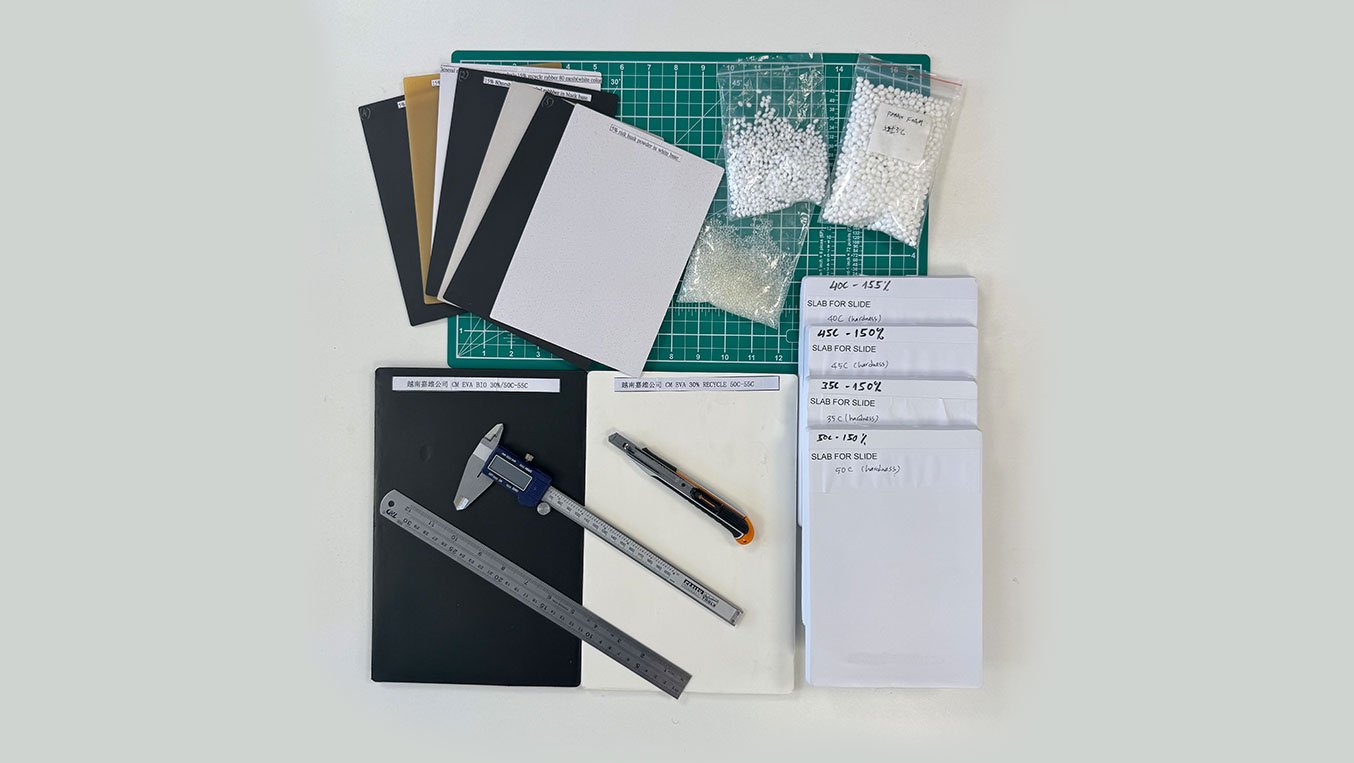

On-the-Ground Compound Development for Midsoles and Outsoles

While uppers define style, it’s the midsole and outsole that shape performance and wearability, especially in sport, lifestyle, and hybrid footwear. For challenger brands, creating custom compounds that balance comfort, responsiveness, and durability can be a technical and cost-heavy challenge.

Vietnam’s compound houses and outsole factories are increasingly offering in-house development services, working directly with brands and sourcng companies to fine-tune EVA blends, rubber densities, and tread patterns. Whether a brand is looking for a lightweight performance midsole with added rebound, or a high-abrasion rubber with specific slip ratings, local teams can prototype and iterate quickly.

This compound development is deeply integrated with local tooling and moulding expertise, meaning ideas move from formulation to testing to production with minimal delay. It’s an agile way to build functional credibility into the product without needing huge R&D budgets.

-

Sustainable and Scalable Options That Work in Production

Brands often lead with purpose, and materials are a key part of that story. The demand for recycled polyester knits, plant-based foams, water-based adhesives, and GRS-certified synthetics is growing. But not all sustainable materials are ready for production, especially in performance footwear.

With access to certified regional suppliers and direct feedback from factory floors, the right team can recommend sustainable solutions that not only support brand values but also meet durability, consistency, and production efficiency standards.

This alignment between values and viability is what allows challenger brands to scale responsibly, not just ideologically.

Wrapping Up

For brands entering the footwear market, looking to push design boundaries while building real product performance, Finding a team with material development at source will offer you a unique edge. From upper fabrics to midsole compounds, these local teams combine creative adaptability with technical know-how and a direct connection to the suppliers.

The result? Faster development, better material choices, and products that are more aligned with both brand identity and consumer expectations. In today’s footwear landscape, that’s not just a competitive advantage; it’s essential.